Vapor Absorption Machine: A Sustainable Cooling Solution

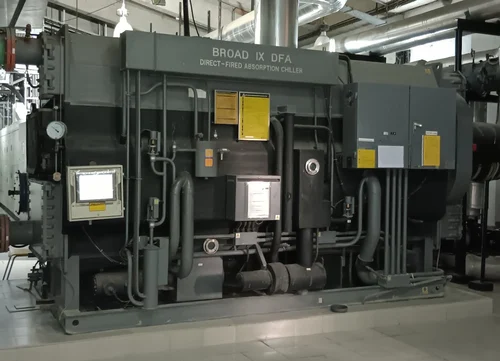

A Vapor Absorption Machine (VAM) is an advanced cooling technology that leverages heat energy instead of electricity to drive the refrigeration process. Unlike conventional vapor compression systems, which rely on electrically powered compressors, a Vapor Absorption Machine operates by using an absorbent-refrigerant pair, such as lithium bromide and water or ammonia and water. This system makes VAM an environmentally friendly and energy-efficient alternative for industrial and commercial cooling applications.

How Vapor Absorption Machines Work

The working principle of a Vapor Absorption Machine is based on the absorption cycle, which consists of four key stages: evaporation, absorption, regeneration, and condensation. The refrigerant evaporates at a low pressure, absorbing heat from the surroundings to produce a cooling effect. The vapor is then absorbed by a solution, forming a high-concentration mixture. This mixture is heated to separate the refrigerant, which then condenses back into a liquid form to repeat the cycle. Unlike traditional compression-based systems, VAMs rely on waste heat or alternative energy sources, making them highly efficient in industrial applications.

Benefits and Applications

Vapor Absorption Machines offer several advantages, including lower energy consumption, reduced carbon footprint, and the ability to utilize waste heat effectively. They operate with natural refrigerants such as water and ammonia, which have minimal environmental impact. VAM systems are widely used in power plants, large commercial buildings, chemical industries, and district cooling applications where sustainability and cost-efficiency are priorities. Their quiet operation and minimal maintenance requirements further enhance their appeal for large-scale cooling needs.

Conclusion

The increasing global focus on energy conservation and sustainability has driven the adoption of Vapor Absorption Machines in modern HVAC systems. As industries continue to seek greener and more cost-effective solutions, VAM technology presents a viable alternative to traditional cooling methods. With advancements in material science and integration with renewable energy sources, VAM systems are expected to play a crucial role in the future of climate control and industrial cooling solutions.

Contact Us now to join the revolution!